Equipment for the synthesis of nanosized powders

Conductor electric explosion denotes the explosive destruction of a metallic conductor when a very high-density ultrashort current pulse is transmitted through it. Conductor destruction results in the generation of metal pairs and extremely fine particles. The resultant particles are distinguished by dimensional, structural, phase, defect and other power-saturated states entailing particular properties for the finished product.

Under certain conditions, the particles obtained via electric explosion may interact with the atmosphere inside the reactor and form various chemical compounds. Depending on the content of the atmosphere inside the reactor, powders of metals, alloys, chemical compounds and blend compositions may be obtained.

- Specifications

- Options

- Application

- Equipment

- Gallery

The method of electric explosion has a number of significant benefits compared to other methods for the synthesis of nanosized powders. Its advantages are as follows:

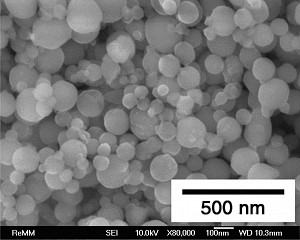

- It enables the generation of spheric-form particles with very high dislocation content (defects of cristal/metal matrix) and margin of internal energy, which significantly enhances chemical potential and gives rise to high physical and chemical activity for the particles.

- When the method of electric conductor explosion is used, power is supplied to the metal volumetrically via impulses; the power consumption is relatively low. Due to this feature, the power consumption involved in the electric explosion method is dramtaically lower than that of other physical methods.

- The method permits fine and flexible control of the parameters of the process and thus the properties of the resultant nanopowders.

- The method enables the production of a wide range of nanopowders of different metals and alloys, which can be made as a wire or foil. In some cases, the method is applicable for flows of molten metal.

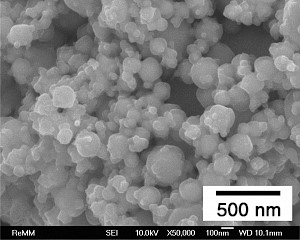

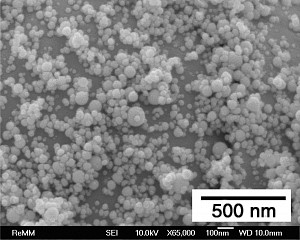

Products manufactured with the EEC method

Our approach is based on the conductor electric explosion method (EEC method), which means that it enables the manufacture of a wide range of nanopowders of metals, its derivates (oxides, nitrids, sulphids), intermetallic compounds and their further modification products such as nanofibers and other nanopatterned entities.

Nanopowders obtained with the EEC method are characterised by the following useful properties, distinguishing them from those produced with other methods:

- low sintering temperature (for example, silver powder sinters at about 700 С, tungsten powder -at 4000 С);

- Stability of electrophysical properties in the low temperature area;

- Abnormally high value of the factor of electromagnetic emission absorption within a wide frequency range;

- Presence of excessive (stored) power;

- Capability to form various intermetallic compounds (even such as W-Al), which is impossible with direct alloying, and plymetals (for instance Cu-Al2O3). Thus, nanopowders may be used as initiators for the sintering of metals, ceramics and a number of other materials

|

Parameter |

Мaterial |

Average size of particles |

Specific surface area |

Purity |

|

Nanopowders of pure metals and alloys |

Al, W, Fe, Cu, Mo, Ni, Ag, Ti, Zn, Cu-Zn, Ni-Cr, etc. |

from 50 nm |

up to 25 m2/g. |

up to 99,9+%. |

|

Nanopowders of metal oxides |

Al2O3, Fe3O4, CuO, etc. |

from 30 nm |

up to 30 m2/g |

up to 99+% |

|

Nanopowders of nitrids, carbides and other metal derivatives |

AlN, TiN, WxCy, etc. |

from 30 nm |

up to 30 m2/g |

up to 99+% |

|

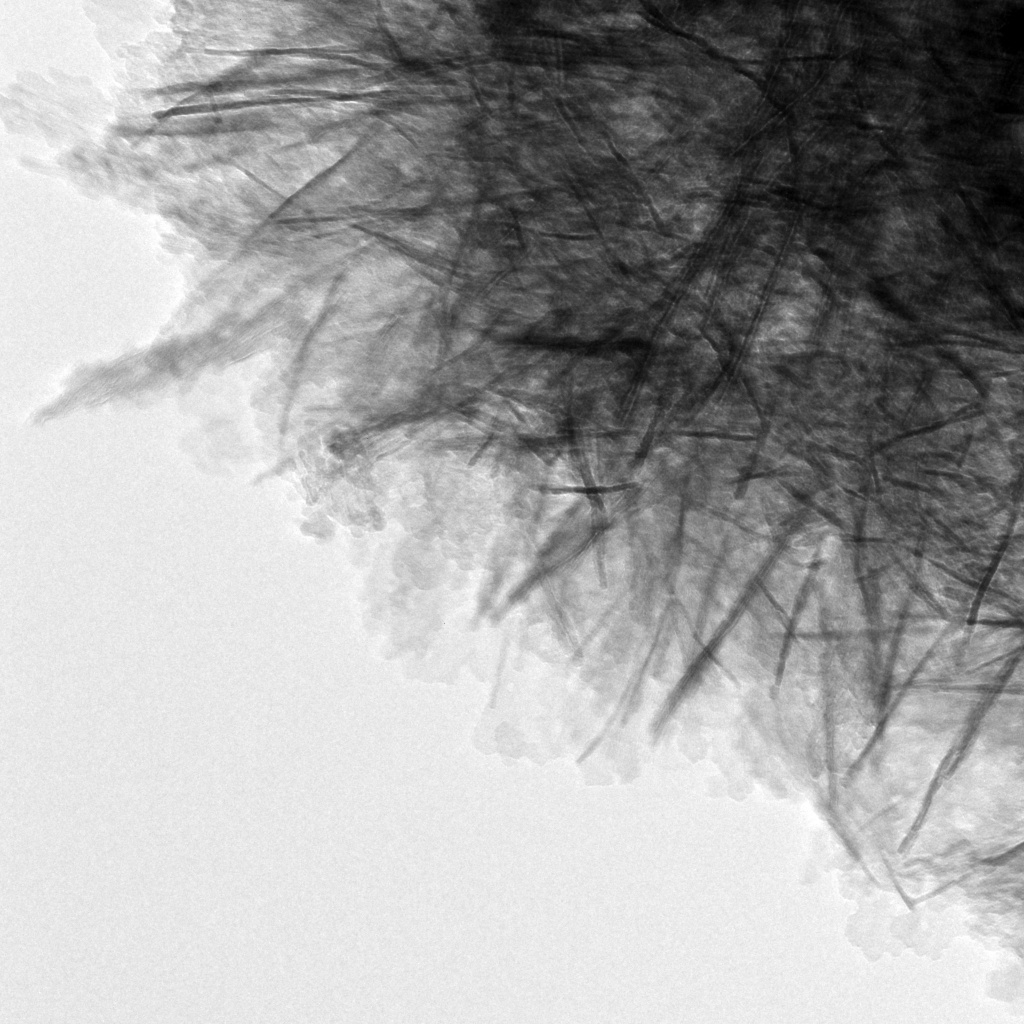

Nanofibres of aluminium compounds |

AlOOH + Al(OН)3 + Al2O3 |

Fiber diameter – 10-15 nm, fiber lenght - up to 500 nm |

up to 500 m2/g. |

up to 99+% |

- Gas absorbers and cathodes of gas-discharge lamps;

- Compounds of fuels, pyrotechnic compositions and explosives;

- Fuel elements, generators of hydrogen and other gases;

- Catalytic agents and reactive chemicals for fine and industrial chemical synthesis.

- The use of nanopowders improves the properties of ultra-strength high-density materials (for example, W-Ni-Fe); special composite materials (for instance, magnetic- Nd-Fe-B, superconducting materials- Ba-Cu-O, Ba-Fe-O) and the mechanical parameters of resins and polymers.

- Electrically and heat-conductive polymers, pastes and paints.

- Greases. Oil additives.

- Manufacture of buffing compositions, semiprecious stones.

- Purification of water, water solutions, other liquids and gases. Filtering materials based on nanofibres. Modification of filtering materials and membranes.

- Nanotechnologies in medicine: drug transport; new pharmaceuticals based on nanopowders for antineoplastic therapy, healing burns and wounds.

- Nanoparticles of many materials (for example, silver and copper) have a strong antiseptic effect. Manufacture of materials, paints, varnishes and coatings with antiseptic properties.

- Powdered cathodes and electrocontact materials.

- Solder compounds with a low soldering and high unsoldering temperature for combining dissimilar materials (glass-metals, semiconductor-metal, precious stones-metal, etc.).

- Composite pastes for applying functional metallic layers, for example, for solar converters.

- Cluster and magnetic fluids. Fluid coolants.

A complete set of equipment for the synthesis of nanopowders includes the following: tools directly used for the synthesis of nanopowders, power unit for charge formation and control, glove boxes for work in the inert atmosphere, natural gas and vacuum equipment, packaging equipment, etc.

The capacity of a unit for the synthesis of nanopowders depends on a number of factors, the most important of which are the nature of the metal (primarily its density), the diameter of the wire used in the process and the size (activity) of the nanoparticles obtained. The average capacity of a unit is approximately 120 g/h for Al / Ti / Mg, 220 g/h for Ni, Co, 340 g/h for W, Cu, Ag etc. The method enables free scaling of manufacturing facilities; complex systems which produce up to 10 t of nanopowder annually are in use today.

Each unit enables the synthesis of a wide range of nanopowders of metals, metal oxides and chemical compositions.

The unit for nanopowder synthesis is universal; to start synthesis of a new powder type, the operator only has to

clean the reactor and replace some standard components.

A complex system for nanopowder synthesis operates at 25-40 kV; the powders manufactured are inflammable. Thus,

special requirements must be observed when preparing facilities and working areas for the production of nanopowders.

EEC equipment must be installed in sound-proof, properly grounded and well-ventilated bays. Furthermore, the power

supply system should be provided with electromagnetic protection to combat voltage surges. Areas intended for

processing and storing metal nanopowders should be equipped with a fire-alarm and fire-fighting systems, as these

materials are inflammable.

Crystal Technologies s.r.o. offers delivery and commissioning services for the equipment sets required for the synthesis of nanopowder of specified types and capacities. The range of services offered includes the following:

- Development of a set of equipment for nanopowder synthesis of the required capacity;

- Generation of a plan for necessary engineering solutions and assistance in the preparation of the customer’s facilities for nanopowder production;

- Manufacture, delivery and commissioning of nanopowder synthesis equipment;

- Delivery and activation of auxiliary equipment;

- Development of process modes for the synthesis of nanopowders of specified types and parameters;

- Training the customer’s staff in the operation and specified maintenance of the equipment;

- Supplying further spare parts and consumables.