Diamonds with carbon coating

This functional material is intended for the development of the mechanical and thermal sustained metal – diamond and metal - dielectric types of composite materials, with various physical and chemical properties.

The coating of the diamond with various carbides allows to resolve two important issues: to provide the necessary wettability between the materials of matrix and reinforcement and to disable the unwanted chemical reaction between materials of matrix and reinforcement.

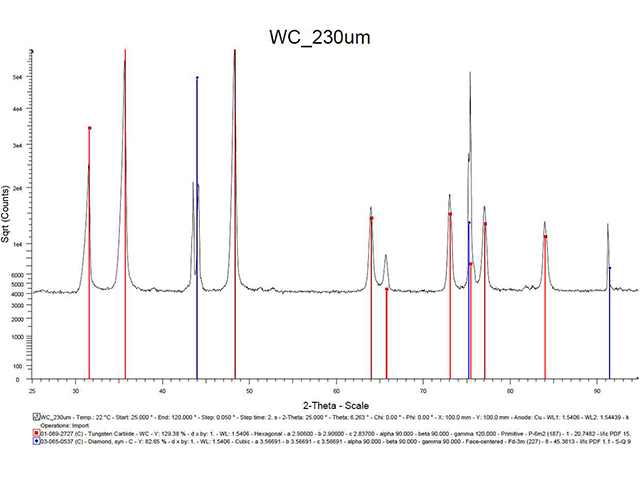

Depending on the matrix material, to ensure of maximum wettability, it is possible to use various types of carbides – WC, MoC, TiC, B4C

- Description

- Application

- Gallery

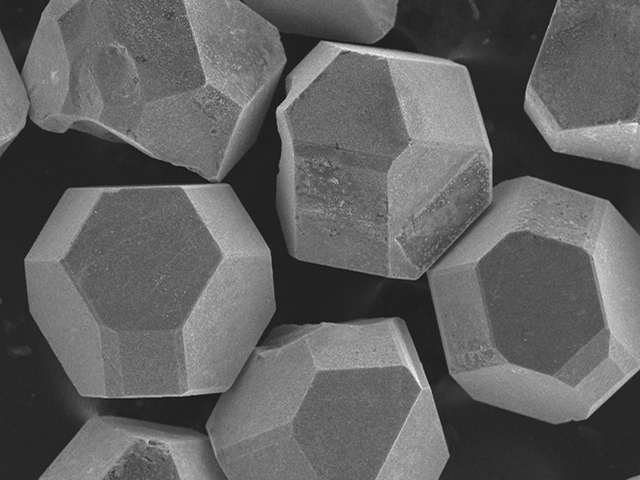

Content of diamond .......................................................................................................................................................... from 90% to 99%

Size of the diamond fraction .......................................................................................................................................... from 2 µm to 500 µm

Composition of coating ................................................................................................................................................... WC, MoC, TiC, B4C

Thickness of the carbide coating .................................................................................................................................. from 50 nm to 2000 nm, with accuracy ± 20%

- Improvement of durability and hardness of the cutting elements of the industrial machine accessories

- Improvement of the thermoconducting properties and coefficient of thermal expansion in the products for heat allotment for power electronics

- Improvement of the mechanical durability, the Young`s modulus and the wear resistance in a various metal products and components.